Eco-Retrofit Keere Street, Lewes

Project type: Residential eco-retrofit

Project location: Lewes, East Sussex

Located towards the bottom of one of Lewes’ steepest and most historically sensitive streets, Deeper Green’s challenge with this property was to turn an energy hungry building, with poor thermal comfort and excessive internal surface condensation issues, into a more comfortable, healthier and easier to heat property.

Image credit: Client

The clients had lived at the Keere Street property since 2013. Soon after moving in, they had the street facing single-glazed sash windows draught-stripped and had injected cavity wall insulation blown into the external wall cavities. Whilst the property was marginally warmer in the winter months, the presence of internal surface condensation massively increased. Even with a large de-humidifier working 24/7, the issue continued. The clients appointed Deeper Green to see if they could help resolve these long-standing issues.

Deeper Green did a thorough visual and measured survey of the property. They then carried out a heat loss calculation and ventilation assessment. They estimated that it was insufficient extract ventilation and replacement fresh air that was likely to be main culprit of the high levels of internal relative humidity.

Deeper Green’s challenge with this property was to turn an energy hungry building, with poor thermal comfort and excessive internal surface condensation issues, into a more comfortable, healthier and easier to heat property.

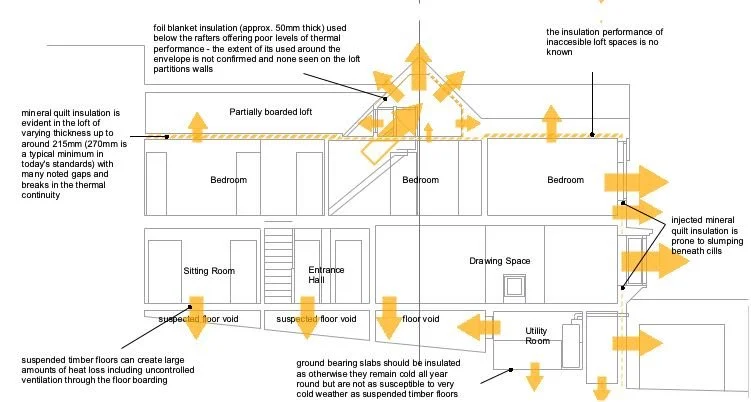

ORIGINAL HEAT LOSS ANALYSIS

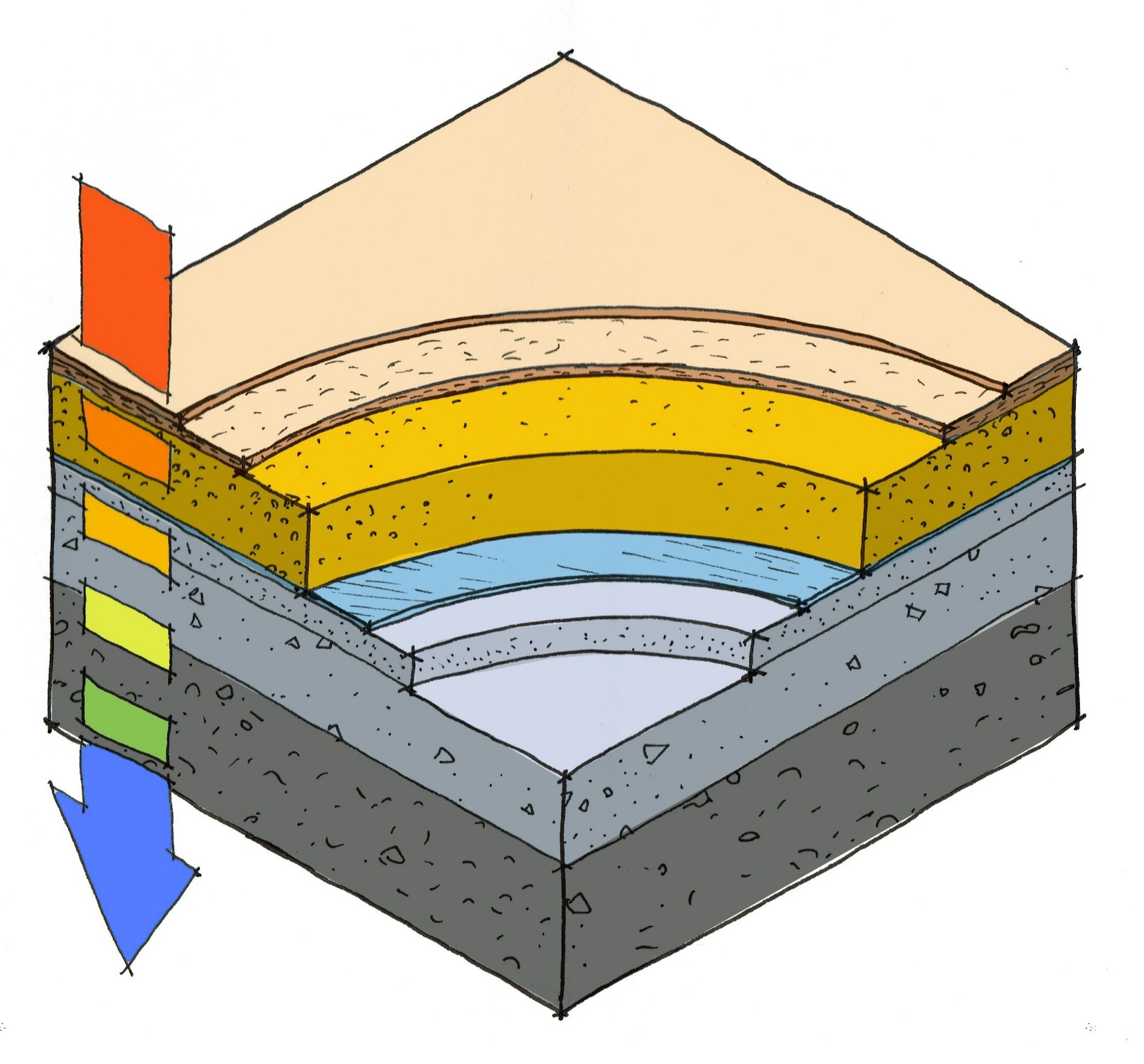

Deeper Green’s visual analysis of the heat loss pathways found around the long-section of the house. A modicum of thermal efficiency work had been done to the external walls which were mostly built as cavity blockwork in the 1950s and glass quilt insulation in the loft spaces of varying quality and thickness. Of particular note, was a 2010-built open staircase up to a small area of converted loft space.

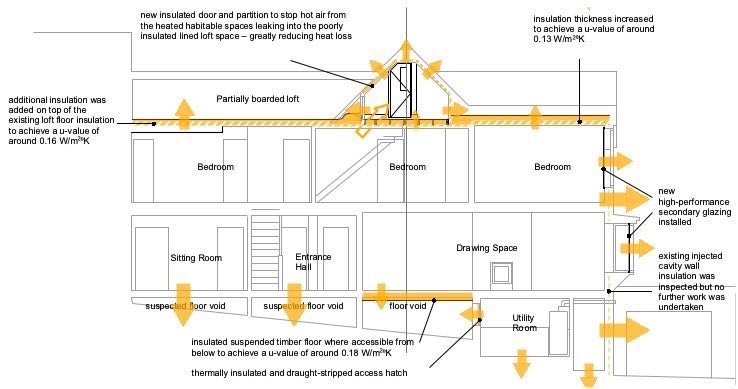

POST ECO-RETROFIT HEAT LOSS ANALYSIS

The thermal efficiency improvements were carefully assessed relative to their cost benefit ratio. A shortlist of measures were taken through to execution.

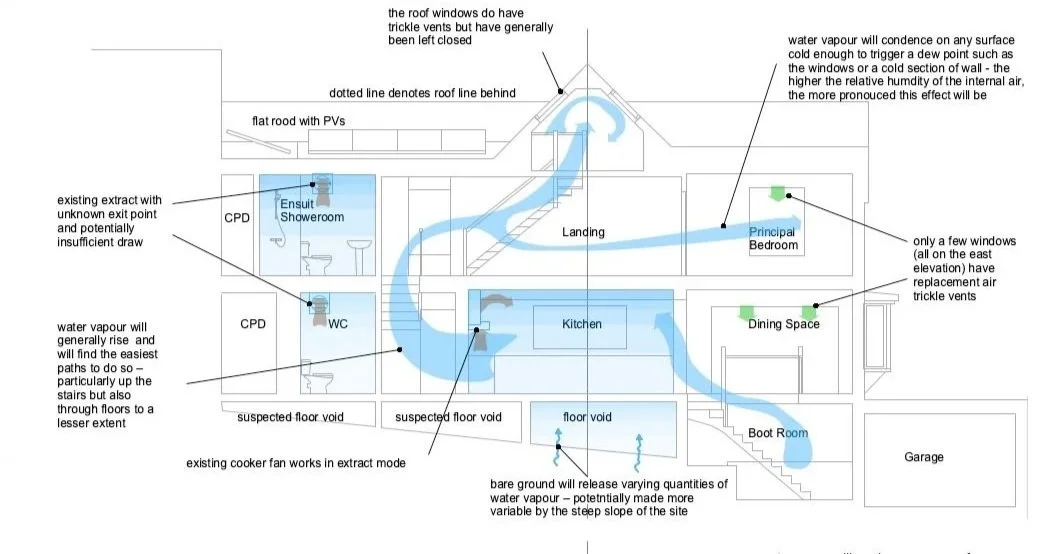

ORIGINAL VENTILATION ANALYSIS

Deeper Green’s visual analysis of the sources of water vapour in the property (not including the occupants). Large amounts of moisture were also being released via the floor voids which were exposed to bare ground. Only a few windows on the garden side of the house had trickle vents. Whilst there were a few intermittent bathroom extract fans, without enough apertures to let replacement fresh air in, the fans were not able to create efficient airflows elsewhere in the house. And these conventional ventilation units only worked while the lights in the bathrooms were on, with a short overrun.

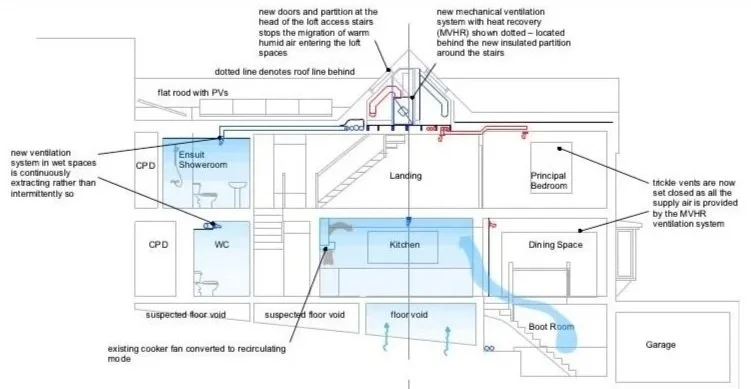

POST ECO-RETROFIT VENTILATION ANALYSIS

Due to heritage restrictions on the street facade, it was not economically viable to retrofit the sliding sash windows with trickle vents. In the end, a full mechanical ventilation system with heat recovery was pursued. This way, there would always be a guaranteed amount of fresh supply air being brought into the house and a corresponding amount of extract air taken out. Routes for the supply and extract air ducts had to be found all over the house.

The property was large and consisted of three or four significant eras of construction. Confounding first impressions, most of the house was built in the 1950’s and with fair-faced and painted cavity blockwork construction. A two-storey extension was added around 2010. This included a partial loft conversion. The space was not habitable but it did include a modicum of insulation around the lined walls, skeilings and ceilings. Unfortunately the open staircase, built as part of these previous works, provided an unhindered exit route of heat and ventilation from the habitable spaces of the ground and first floors. By introducing an insulated stud partition and draught-stripped door at the head of the stairs, the 2024/25 works tightened-up the treated ‘thermal envelope’.

To resolve the internal moisture issues, the Deeper Green analysis looked primarily at increasing controlled ventilation within the property. The initial proposal was to introduce a continuous mechanical extract system. However this was contingent on introducing trickle ventilation to most of the windows of the property. From discussions with the Conservation Officer, we learned that conventional retrofitted trickle vents for the windows facing onto Keere Street would not be acceptable. Additionally, having opted for secondary-glazing instead of vacuum-glazing as a means of thermally upgrading all the single-glazed windows, window-mounted trickle vents would not have worked anyway. Thus, we opted for a whole house mechanical ventilation system with heat recovery (MVHR). MVHR relies on a centralised ventilation unit with lots of air ducts. It has a fan pumping in fresh supply air to the habitable spaces of the house and a second fan extracting stale air from the ‘wet’ (bathrooms, kitchen, utility) spaces.

For the secondary-glazing, although magnetic and vacuum-glazing were considered, Deeper Green sourced an advanced system with varying solutions depending on whether the existing window was a casement or sliding sash typology.

To allow the project to take best advantage of 0% VAT rated energy efficiency measures, the project was broken up into three distinct phases. The first phase, which involved the secondary-glazing, the loft alteration work and the installation of the ventilation system, was 20% VAT rated work. The second phase included the bulk of the thermal upgrade work which was 0% VAT rated as was the third phase, which was the heat pump installation.

Only the most cost beneficial options were selected to go forward to execution. This included the upgrade of the loft floor insulation, much of which was integrated with the MVHR ducting. The skeilings of the 1st floor bedrooms had wood fibre insulation boards applied between (with an air gap above) and beneath the existing rafters with a lime plaster finish applied. Where accessible from below, the suspended timber ground floors were insulated between and beneath the existing joists.

All the street facing bedrooms had significant areas of ‘skeilings’ (sloped ceilings) which were completely uninsulated. The solution was to apply a wood fibre insulation batt between the rafter (leaving an air passage above) and below the rafter and then finish with a ‘breathing’ plaster finish with mineral paint decoration. Here you see the thickness of the new construction where it terminates with the reveal of a dormer window. This work has made a huge improvement to the thermal comfort of the bedroom spaces.

The upgraded loft floor is seen here with its second layer or hemp insulation (note the new cross joists) and the relayed floor boards. The photo was taken just prior to the new insulated stud wall being constructed around the head of the stairs.

The new thermally insulated partition consisted of two lines of ex-50×50mm timber studs with a thick batt of hemp insulation laid between – thus removing almost all of the so-called ‘thermal-bridging’ effect normally associated with a timber stud wall.

Mineral insulation was applied between and below the floor joists in one of the tall floor voids below the upper ground floor.

The ventilation system was installed throughout the house in accordance with a carefully planned set of pathways agreed between the Clients, Deeper Green and the MVHR installer. Some of the routing was more disruptive than others. This particularly complex area required a lowered ceiling so the ducts could be routed at 90º to the flat roof joists above.

No less than five extract and supply air ducts came through the Breakfast Room space.

The completed boxing out of the MVHR ductwork in the Breakfast Room.

The ultra-slim secondary-glazing used on the casement windows of a feature bay window were deemed a big success by the clients. These units individually and effortlessly slide horizontally to afford access to the old windows behind. Prior to sign-off, the Conservation Officer reviewed a sample corner section of the unit and was happy with the external appearance.

It was deemed the energy efficiency upgrades taken forward would result in reasonably low running costs for using a heat pump. In this case, a Samsung 16kW monobloc unit was installed in addition to a number of upgraded radiators around the house. Even during the coldest nights of the first winter in use, the new heating system has successfully met occupant heating demands.

The client was keen to improve the efficiency of their existing photovoltaic array. An overhaul of the system included installing an optimiser and a 20kW modular battery. In the winter months, when the solar harvesting is much reduced, the battery also takes advantage of low cost night-tariff electricity.

The work included the termination and removal of the gas heating system and the transition to electric heating with the installation of this 16 kW air source heat pump.

The new and much enlarged hot water tank working in conjunction with the air source heat pump.

With 6 wet spaces and 10 habitable spaces to extract and supply air to (respectively) the MVHR and its associated ductwork was a particularly large and complex installation.

The electrical storage battery, which the client pursued separately but as part of the 2025 phased set of works, stores energy from the solar panels and also charges up on night tariff electricity, especially during the winter months. This in turn helps power the heat pump.

The clients opted to live in the property during the works – not a process they would like to repeat but they were very complimentary about the way in which the Contractor tried to minimise disruption.

The retrofit project achieved all the main objectives of the clients. The rampant internal moisture issues have been erradicated and, even though only a small number of thermal envelope upgrades were affected, there is a huge improvement overall in thermal comfort experienced around the house. The clients are particularly impressed with the secondary-glazing and the way the ventilation system distributes drier and more comfortable air around the house. The Deeper Green feasibility study estimated the carbon reductions on heating alone to be in the order of 80% (based on carbon intensity of the National Grid in 2024), ie. 4.7 tonnes using a gas boiler down to around 0.9 tonnes for powering a heat pump.

After half a year of post-works bills, the clients estimate they will be spending about £1,500 on their ongoing energy costs. This compares to the combined gas and electricity for 2023/24 of around £3,500. With a £2000 per year energy cost saving, it will still take decades to pay-off the eco-retrofit investments. However, this project was never primarily about pay-back periods. Its fundamental goals were an overall improvement in thermal comfort and an eradication of the problematic internal surface condensation. On that front, the project has been a huge success.

Team credits:

Client: Private

Architects: Deeper Green Limited

Main Contractor: Hartley Quinn-Wilson

MVHR Installer: Built Environment Technology Limited

Heating Engineer: Aspens AC and Renewables Limited